Indoor Cultivation

To begin your indoor cannabis cultivation project, you will need to invest in some equipment and supplies which we will get into below.

First you will need to decide where you would like to set up your new grow space, many people tend to start out in the garage or spare room.

With that in mind lets discuss the basics.

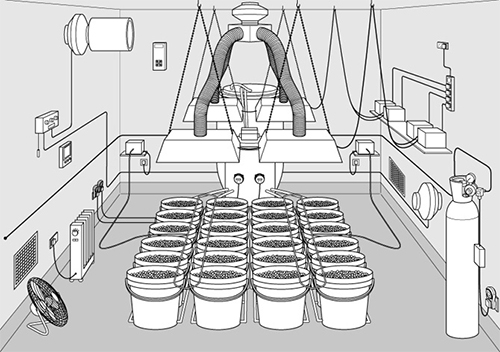

A grow tent is a common item, they come in various sizes and with various exhaust vents, they tend to be made out of a heavy black canvas material with a reflective interior material with zipper doors and windows.

Cannabis grow tents are fairly easy to set up with a pole and plastic corner pieces that make up the support structure for the canvas-based shell to cover.

The support structure will have poles along the interior ceiling for hanging lights.

Lights are the next important piece of your setup and come with a variety of options to choose from, including High Pressure Sodium, Metal Halide, Florescent, and LED and come in various wattages also from 200 watts to 400 watts, 600 watts, and up to 1000 watts.

Hight Intensity Discharge lights or HIDs will be a less expensive option, but also require a large enough exterior ballast to drive the lights.

L.E.D. lights are more efficient and lasts longer which makes them a pricier option.

Florescent lighting can be used, but these options usually don’t pack the punch of the other lighting options and will have an effect on your outcome.

HIDs tend to run hotter than other lights and the heat needs to be removed from the grow room and area in order to keep the heat at a minimum, so you don’t cook your plants.

Given the heat produced by HID lighting, special reflective light hoods are used known as “Cool Tubes” that connect to an inline fan to pull air through the glass tube where the lamp is placed, which in turn pulls the heat from the lamp through ducting and directed out of the grow room.

While the use of Cool Tubes does help reduce heat somewhat, it doesn’t completely eradicate the heat since HID lamps also

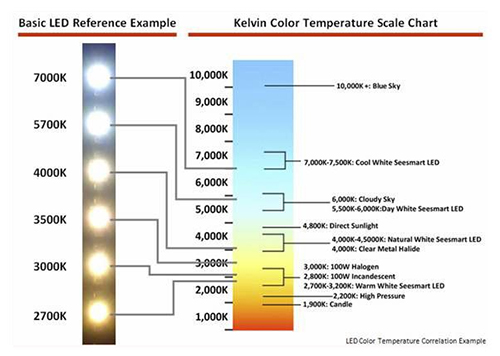

Most High-Pressure Sodium HID lamps are in the lower spectrum of the Kelvin range being anywhere from 1900k to 2400k putting them in the red color spectrum and gives them their signature orange appearance.

High Pressure Sodium lights are mainly used during the flowering stage because their Kelvin range is perfect for this stage of the plant’s growth.

Metal Halide HID lamps Kelvin range is anywhere from 4000k to 6500k giving them a more Daylight or blue appearance. This range is specifically for the vegetative stage of plant growth.

Today’s L.E.D. technology has shifted from either a vegetative or flowering Kelvin range to a more Full Spectrum range of roughly 5000 Kelvin. Due to this, the lamps no longer need to be switched out upon entering the flowering phase and can run through both stages with excellent results.

L.E.D. lamps also operate cooler than HID lamps due to their setup of displacing heat through built in Heat Sinks, this allows less energy requirements for cooling the grow room.

The downside to L.E.D. lighting is the intensity of the diodes themselves, this intensity can cause the plant to react poorly, so the lights will require more distance between themselves and the top of your canopy, this can a challenge in a shorter grow tent or space.

You will need a light timer or two depending on your setup, this is where you will control your light cycle, being either 16hrs for vegetation or 12hrs for flowering.

Now that you have a grow space and lighting taken care of, it’s time to delve into what type of grow setup you will use.

There are several options with Soil, Hydroponics, and Passive Hydroponics being the most popular.

Soil grows are fairly straightforward, containers, a well put together soil specifically designed for cannabis cultivation and the proper nutrients designed for soil feeding is all that’s required.

Hydroponics is a little more complicated and requires more attention in order to keep up with the continual changes in water temperature, PH, and PPMs.

Hydroponic systems can be purchased premade, or in many cases built to suit the grow space by constructing a system from food grade containers, through hull fittings, and pvc pipes.

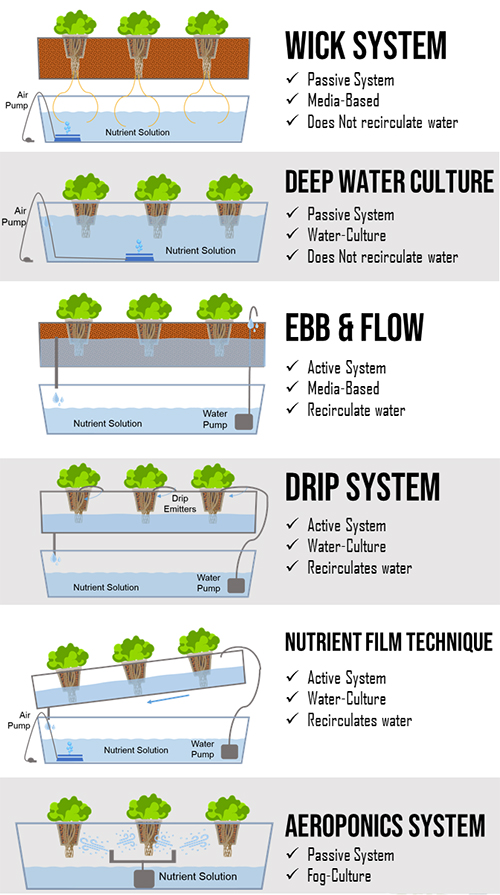

There are a few various types of hydroponic systems that include Deep Water Culture, Nutrient Film Technique, Ebb and Flow, Aeroponics, and Drip Systems.

Many of these Hydroponic systems utilize a reservoir and a water pump that send the reservoir water through tubing into the top of the grow containers that then drain from the bottom and sends the water back to the reservoir where it starts the cycle all over again.

For many hydroponic systems, the preferred grow medium is Hydroton used with net pots.

Air pumps and bubblers are used in each container, as the bubbles reach the surface and pop, the nutrient water splashed on the Hydroton, which in turn wicks up and keeps the newly forming roots hydrated so they can continually feed.

Once the roots have grown down past the Hydroton and into the container of water, the bubbler continues to add much needed dissolved oxygen to the feed and the system.

Grow rooms can tend to get fairly warm due to the lighting which in turn heats up the water, in an effort to keep the water temperature in an acceptable range, water chillers are typically utilized to control this factor.

Evaporation will also take place in the Hydroponic grow rooms which requires a regular top off with PH balanced nutrient water, as the water level drops the PH changes and also may require adjustments.

Given the additional attention and equipment required for Hydroponic systems, they do however provide incredible results and a fast turnaround, this also means that things can go bad quickly, so any issues need to be addressed just as fast.

Passive hydroponics is another popular form of plant cultivation which gives the same results of hydroponics but with less equipment and time required.

One of the more popular passive hydroponic systems is known as Dutch Buckets or Internal Reservoir buckets. These are buckets that allow nutrient water to settle at the bottom of the buckets with an overfill hole that additional nutrient water can be expelled. The plants roots will grow down into the reservoir and feed on the nutrient water continually, then all that needs to be done is a replacement watering to refill the reservoir.

Passive hydroponics relies less on water temperature and PH/PPM fluctuations since the water is usually replaced daily and the plants just feed from the reservoir

Coco tends to be the preferred grow medium using a passive hydroponic system since it brings nothing to the grow other than a material that sustains the plant root system and its ability to wick up the nutrient rich water keeping the entire grow column wet.

Oscillating fans are a good choice for indoor grow operations, they move air and simulate wind, which in turn bends the stem of your plants, which in turn breaks their cell walls which upon repair makes the stem stronger.

Wind also forces the plant to release a hormone called auxin that stimulates the growth of supporting cells.

Carbon Filters are a normal include in any home garden, while not necessarily needed in the vegetative stage, they will certainly come in handy during the flowering stage.

Carbon filters are usually connected to flexible ducting and an inline fan that’s fed inside the grow room and either sucks air out or pushes air in, either way, the grow room air is scrubbed using the carbon filter to reduce odor.

Air conditioning is an item that you may or may not need for your grow room, it really depends on whether you’re going to set up your room to be sealed or allow ventilation as well as the environmental conditions of your area.

Mini split air conditioners have become more and more popular in today’s personal cultivation section as they are fairly inexpensive, energy efficient, whisper quiet, and does not require ducting.

Many mini split air conditioning systems also come with heat pumps, so they act as both air conditioner and heater.

Humidifiers and Dehumidifiers is another one of those items that you may or may not require, normally if growing in a sealed room and not ventilating with outside air, humidity will tend to build up and a dehumidifier will be employed to control the issue.

If ventilating or exchanging the room with fresh air, depending on the daily environmental conditions, the rooms humidity could be low, so a humidifier would be required to bring the rooms humidity into a more acceptable range.

CO2 is yet another item you may or may not need depending on whether your room is sealed or ventilated.

CO2 can be accomplished in a couple of ways, via a tank or a propane burner.

Most hobby growers will use a CO2 tank that can be swapped out at your local hydroponics store, this tank is connected via a regulator to a control unit which measures the amount of CO2 in the room and opens the valve on the regulator to allow the CO2 to be added to the room until the CO2 levels have reached your input value.

Propane burners are used in larger rooms and consist of a unit connected to a propane tank, the unit has a pilot light and connected to a control box that lights the burners when CO2 levels have dropped, by burning the propane, it creates CO2 that is distributed throughout the room.

Inline fans are a necessary item in a ventilated grow room, they are used to provide ventilation and remove heat from the space.

Some incidentals will be required also such as flexible ducting, yo yo lighting cables and gardening sheers for the most part.